Pressing Instruction & Tips

Our DTF transfers can be pressed on any clothing material or fabric!!

Gone are the days where you are limited in clothing materials or other fabrics. Whether it is 100% cotton, 100% Polyester, 50%/50%, or anything in between... You can press on it!

100% Cotton

We recommend a heat setting of 275-300°F while pressing this material at 60-80 PSI.*

- Pre-Press (Optional): 5 seconds on shirt without design on it.

- Design Press: Put your graphic on the shirt in your desired placement and press for 15 seconds.

- Post Press: After you peel** your design, press for 5 seconds to seal it to the shirt!

Blends

We recommend a heat setting of 260-280°F while pressing this material at 40-60 PSI.*

- Pre-Press (Optional): 5 seconds on shirt without design on it.

- Design Press: Put your graphic on the shirt in your desired placement and press for 20 seconds.

- Post Press: After you peel** your design, press for 5 seconds to seal it to the shirt!

100% Polyester

We recommend a heat setting of 250-265°F while pressing this material at 40-60 PSI.*

- Pre-Press (Optional): 5 seconds on shirt without design on it.

- Design Press: Put your graphic on the shirt in your desired placement and press for 20- 30 seconds.

- Post Press: After you peel** your design, press for 5 seconds to seal it to the shirt!

Nylon

We recommend a heat setting of 240-250°F while pressing this material at 40-60 PSI.*

- Pre-Press (Optional): 5 seconds on shirt without design on it.

- Design Press: Put your graphic on the shirt in your desired placement and press for 15- 20 seconds.

- Post Press: After you peel** your design, press for 5 seconds to seal it to the shirt!

But Wait... There's More!!

-

Leather

We recommend a heat setting of 260-275°F while pressing on leather at 60-80 PSI.*

- Pre-Press (Optional): 5 seconds on your material without design on it.

- Design Press: Put your graphic on the material in your desired placement and press for 15- 20 seconds.

- Post Press: After you peel** your design, press for 5 seconds to seal it to the material!

-

Non-Woven Polypropylene

We recommend a heat setting of 240-250°F while pressing on non-woven polypropylene at 60- 80 PSI.*

- Pre-Press (Optional): 5 seconds on your material without design on it.

- Design Press: Put your graphic on the material in your desired placement and press for 30 seconds.

- Post Press: After you peel** your design, press for 5 seconds to seal it to the material!

-

Neoprene

We recommend a heat setting of 240-250°F while pressing on neoprene at 40-60 PSI.*

- Pre-Press (Optional): 5 seconds on your material without design on it.

- Design Press: Put your graphic on the material in your desired placement and press for 15 seconds.

- Post Press: After you peel** your design, press for 5 seconds to seal it to the material!

Care Instructions

Storage

- DTF Transfers should be stored in a dry and cooled environment. For best results store transfers in a Ziplock bag.

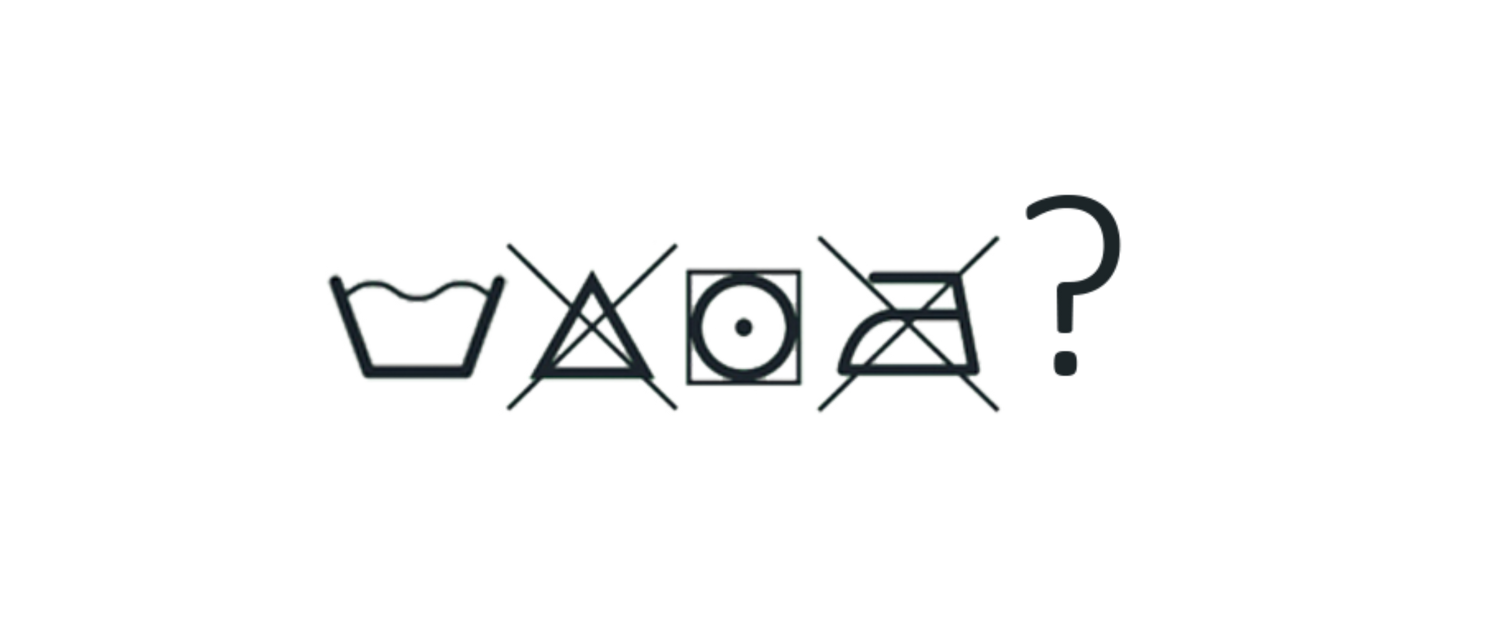

Washing Instructions

- Wash in cool water with like-colored garments.

- Tumble dry on delicate or low setting.

- Do not bleach.

- Do not iron directly on print. If absolutely necessary iron shirt inside out on a low heat setting.

*All temperature, times and pressures

- All temperature, times and pressures may vary depending on the exact materials and heat press used. Be sure to do a test press to find out what is best for you.

**How To Peel Your Transfer

- Hot Peel Pro Tips- After the design press, use a microfiber towel to quickly wipe transfer helping the fine print to adhere on shirt. Then peel immediately (Maximum 5-10 seconds). Don't forget to do a 5 second post press!

- Cold Peel Pro Tips- After the design press, use a microfiber towel to quickly wipe transfer helping the fine print to adhere on shirt. Wait for design to get cool to the touch (Minimum 15-30 seconds) then peel. Don't forget to do a 5 second post press!

Choose Option Below

-

Build Your Gang Sheet

Don't have a ready-to-print Gang Sheet? Use Gregacy's DTF Gang Sheet Builder...

-

Upload Your Gang Sheet

Already have a Pre-Made Gang Sheet that is ready-to-print ? Upload now...